- #Abb robotstudio tutorial book for free

- #Abb robotstudio tutorial book how to

- #Abb robotstudio tutorial book software

- #Abb robotstudio tutorial book trial

- #Abb robotstudio tutorial book Pc

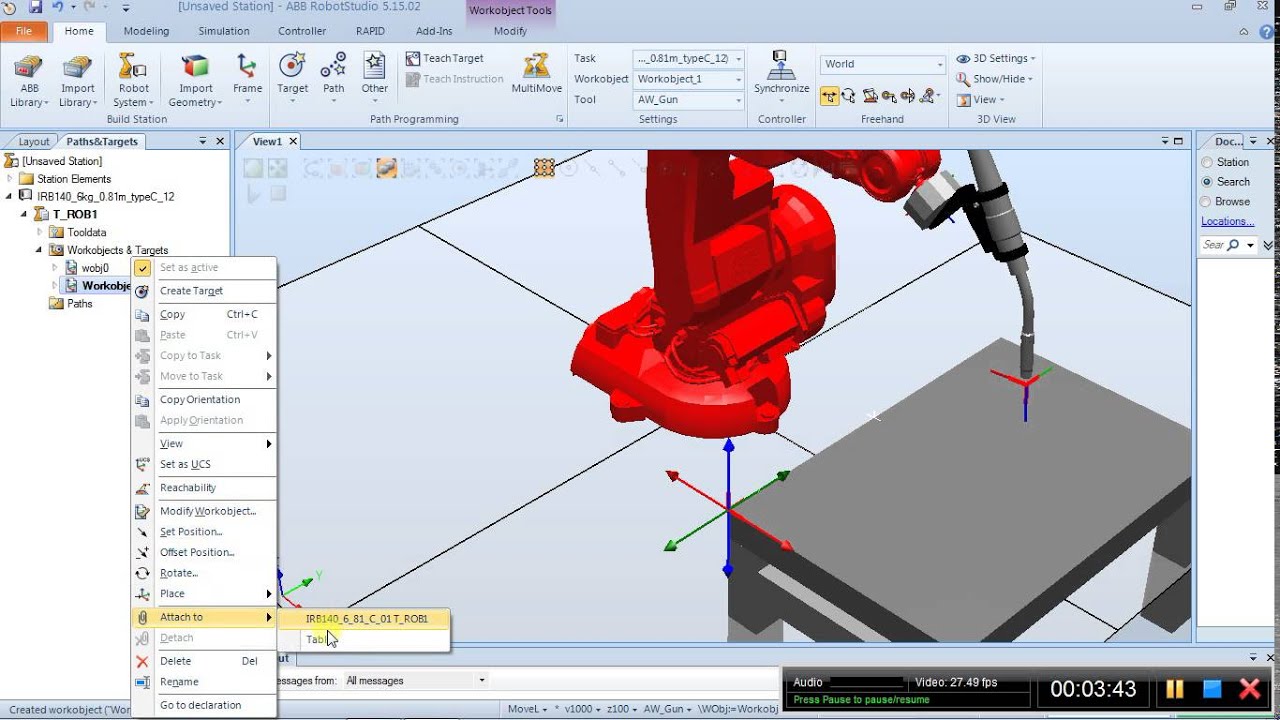

In this tutorial you will learn how to use collision sets to verify that your robot's path is obstacle free.Reply11 months 27 days agoReginaShare On TwitterShare On GoogleHi. This tutorial will show how to configure Collision Avoidance to prevent collisions between robots and equipment, or between robots in a MultiMove system. This Tutorial will show how to create a system Virtual Controller for the imported robot and external axis mechanisms in a station.

A mechanism can be of the type robot, external axis, tool, device or conveyor.Īlso show how to create an external axis. This Tutorial will show how to create a mechanism in RobotStudio. The cable will move in a realistic manner in conjunction with rigid body simulation. This tutorial shows how to create a simulated cable or hose. This Tutorial will show how to automatically create a robot path that follows an edge on a geometry. This tutorial will show how to configure and visualize asymmetric corner zones which are introduced in RobotWare 6.

This tutorial shows how to create a print program with the 3D Printing PowerPac for a robot moved by a linear coordinated track and an extruder tool controlled as an external axis. This tutorial shows how to create a print program with the 3D Printing PowerPac for a robot printing on a rotational coordinated turn table. This tutorial shows how to create a print program with the 3D Printing PowerPac for a robot with an extruder tool controlled as an external axis.

#Abb robotstudio tutorial book for free

What are we providing for free in ? How can you get it?ABB's website uses cookies.īy staying here you are agreeing to our use of cookies. RobotStudio is currently free of charge to help customers maintain production. This allows very realistic simulations to be performed, using real robot programs and configuration files identical to those used on the shop floor.

#Abb robotstudio tutorial book software

RobotStudio is built on the ABB VirtualController, an exact copy of the real software that runs your robots in production. This provides numerous benefits including: Risk reduction Quicker start-up Shorter change-over Increased productivity. RobotStudio provides the tools to increase the profitability of your robot system by letting you perform tasks such as training, programming, and optimization without disturbing production.

#Abb robotstudio tutorial book Pc

ABB's simulation and offline programming software, RobotStudio, allows robot programming to be done on a PC in the office without shutting down production. Offline programming is the best way to maximize return on investment for robot systems. The world's most used offline programming tool for robotics. Your cart Learn more about shopping on ABB. Login to myABB There was a problem with your request. Navigate Search Login layouts-flyoutmenu-cart.

#Abb robotstudio tutorial book trial

Within RobotStudio, just go to: 1 file 2 option 3 licenses 4 request a license 5 trial license 6 special offer Submit your inquiry and we will contact you. By staying here you are agreeing to our use of cookies. Related products.ABB's website uses cookies. Reduce programming time Engineering and commissioning efficiency More cost efficient handling of short batches In control of the process parameters Easy to create and modify parameters Extended tool lifetime Improved path accuracy Improve product quality Seamless integration with RobotWare and RobotStudio. The software will automatically create sufficient number of targets in a path to make sure the path precisely matches the machining requirement. As the targets and paths are automatically generated either from CAD surfaces or CAM code, a consistent and accurate result can be achieved independent of user skills. The different path strategies increase the tool life time by machining with a tool area instead of a single point and cover also different tool contact point for different processes. The integrated postprocessor generates accurate robot paths from the CAM software and utilizes the strength of being closely integrated into the robot controller.Įxtended tool life time and improved path accuracy. It provides several strategies to easily generate machining paths and curves on free surfaces to run the machining program, satisfying different path generation requirements. The Machining PowerPac is the ideal tool for programming of applications such as machining, deburring, grinding, polishing and deflashing. With its new programming methods, ABB is setting the standard for robot programming worldwide.Ĭreating complex paths in just seconds. RobotStudio is the leading product for offline programming on the market. RobotStudio Machining PowerPac is an add-in to Robot Studio, which makes it possible to create complex paths in just seconds! Increased engineering efficiency within machining applications.

Submit your inquiry and we will contact you.

0 kommentar(er)

0 kommentar(er)